Still family-owned and family-run, Oxford has developed from the humblest of beginnings into the UK’s largest distributor of two-wheel aftermarket products and created an international brand to be reckoned with in all corners of the globe.

Now into its 51st year, the Oxfordshire-based brand packs an impressive punch, boasting a range of around 12,000 motorcycle and bicycle products, each one designed, developed and tested in-house at the firm’s R&D centre, part of their 150,000 sq ft empire in Oxfordshire. In the UK, the company also distributes several thousand product lines from some key global brands. And it all started in 1973 with the humble top box…

“Motorcycling was somewhat different in those days,” begins Oxford founder and Chairman, Alec Hammond, who back in 1973 was a 28-year-old sales manager working in the pharmaceutical industry. “There were massive numbers of folk riding to work, and luggage hardly existed.”

Around that time, Alec was introduced to a Nottinghamshire-based innovator who had created a range of high-quality top boxes but had no idea how to get them to market.

“I agreed to show some samples to a few motorcycle dealers whilst travelling in the course of my job,” continues Alec. “The top boxes got a massive thumbs up from several dealers who clamoured to buy them. I became convinced that I could build a business in the motorcycle world, so I left my comfortable, secure job and pushed David to go into full-time production of the boxes.”

Racing ahead

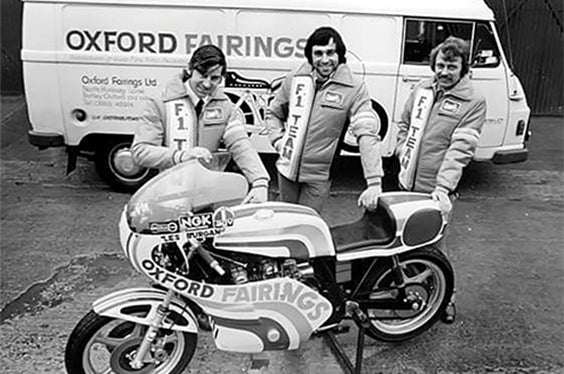

From fibreglass top boxes, Alec quickly branched out into bodywork, and it wasn’t long before the fledgling Oxford Fairings got into the sportier side of motorcycling.

“We got involved with racing fairly early on,” says Alec, “sponsoring several riders with our fairings on Peckett-McNab Kawasakis. This evolved over time until I was running our own team in the equivalent of BSB and at the Isle of Man.”

It was at the TT where Oxford Fairings played their part in one of the sport’s greatest ever comebacks, when Mike Hailwood took glory on the Island after 11 years away from bike racing, as Alec explains:

“We were already marketing a range of GRP fairings made in the UK. I had contacts manufacturing GRP products using carbon-fibre technology, so we replicated everything for the Ducati: fairing, fuel tank, seat unit, mudguards, etc.”

The commitment to racing continued through the ’80s and ’90s with Oxford supporting many big-name riders, including Robert Dunlop, Steve Hislop, Jim Moodie, Jeremy McWilliams, and Trevor Nation. It’s Trevor’s first TT win, the 1984 Production TT, that particularly sticks in Alec’s mind.

“I had a Honda CBX750 as a road bike and we were based in Castletown for the TT and involved with Trevor’s racing in various classes.

“On day one of Practice Week, we realised that my Honda would be eligible — though probably not competitive — for the 750cc Production Class, so we went for it. Long story short, Trevor won by two seconds from Helmut Daphne on a works BMW. A little old private team beating all the factory bikes!”

Constant evolution

Although still very much involved with racing through the title sponsorship of the Moto Rapido Ducati BSB team, the Oxford of today is a far cry from those early days marketing fibreglass fairings and top boxes. In the early 1980s, Alec started manufacturing motorcycle locks, then came accessories — including the now legendary HotGrips, which were born in 1983 and have remained a constantly evolving product in Oxford’s line-up ever since.

But it was in 2010, under the direction of Alec’s son, current Managing Director Andrew Hammond, that Oxford went through its largest transformation yet, as the firm branched out into rider clothing, and at the same time got serious about in-house R&D. “It was a huge investment,” says Andrew. “Particularly in the recruitment of the right team to be able to make it what it has become today. It’s obviously been a slow and long learning curve but, as we are all bikers, it wasn’t too tough.”

Not only is Oxford’s R&D centre staffed by bike-riding designers and engineers, who see each product through from conception to production, but it’s also filled with cutting-edge technology to help them do so. On the accessories side, the team begin by building a 3D CAD model of the product, before subjecting it to ‘Finite Element Analysis’ to test for theoretical areas of weakness or over-engineering, then pressing print and watching as the production-quality 3D printer creates a fully working prototype part.

“The process is a lot of fun,” admits Suzuki GSX-R1000-riding Chief Engineer Kris Doe. “But it literally saves us months of time. In the old days, you had to send the specification off to a factory, then wait to get a prototype made. If it wasn’t right, you’d have to start all over again. But now we can do all our prototyping in-house then send the specification to the factory and they literally can’t get it wrong.”

Investment in people

It’s truly staggering to see the amount of input and testing that goes into each product, even on something as basic as a bike cover — one of Oxford’s biggest selling lines. “We constantly receive pictures of our covers from all over the world,” adds Andrew. “It makes us very proud to see them dotted all over the planet.”

With that in mind, all hard parts and fabrics are subjected to an accelerated aging test in Oxford’s weathering machine, a piece of equipment in their onsite lab that exposes kit to levels of UV and moisture equivalent to two years outside in Florida. After that, everything’s tested to destruction — and all this is in addition to the industry-required CE certification tests, which must take place at an independent external testing lab.

Oxford has learned a lot from other brands in a very short space of time, but also invested very heavily in talent. Some of this has been developed in-house, but much of it has been imported; some from the motorcycle and cycle world, most from sports and leisurewear, bringing experience from big industry and the high street.

Plenty of big motorcycling brands claim to be ‘by bikers, for bikers’ but, by managing to stay privately owned, Oxford say they are truly free to do just that. As Andrew describes:

“I personally swell with pride every time I see our products in use or get chatting to a biker for the first time and they reel off the various Oxford products they own. Usually, my first question is ‘what do you think we should be looking to develop next?’ and, more often than not, it is quickly on the drawing board!”

Oxford's huge range of products encompasses everything which makes life on bikes better: from clothing and helmets to accessories, hard parts, locks, luggage, detailers, and more!